-

Hot

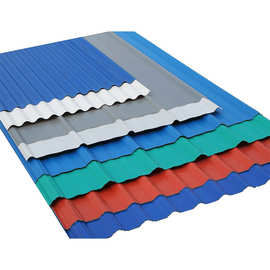

Metal Building Material Prepainted Color Roof Tiles Galvanized Corrugated Metal Roofing Sheet

Metal Building Material Prepainted Color Roof Tiles Galvanized Corrugated Metal Roofing Sheet made from galvainzied sheets directly, Galvanized sheet is a steel plate with a layer of zinc on its surface. PPGI color coated roofing sheets, make the color on the Galvanized surface. Color coated profiled steel plate this new building material has:Light weight, high strength, beautiful and durable, easy installation, fast construction speed, good seismic performance, construction environment is not polluted, easy to factory and assembly construction and other advantages.

Send Email Details -

Hot

Customized Color Coated Aluminium Roofing Sheet Painted Aluminum Coil

Color coating board appearance quality: Color aluminum plate section neat, clean, no burr, crack edge, clamp edge, tower type, loose roll, tube core string out, arrow, string layer, bar, knock injury and other defects, solid welding. Brand & Grade : SGCC/SGHC & Q195 & SPCC Normal Size MM 32mm → 1250mm (Length : booked by client ) Thickness MM 0.12mm ABOVE↑

Send Email Details -

Hot

55% Hot Dipped Al-Zn/ Galvalume Roofing Sheets

1. Thermal reflectivity: Aluminium-zinc steel plate has a high thermal reflectivity, twice that of galvanized steel plate, and is often used as an insulating material. 2. Heat resistance: Aluminum zinc alloy steel plate has good heat resistance, can withstand the high temperature of more than 300 degrees Celsius, and aluminum plated steel plate high temperature oxidation resistance is very similar, often used in chimney tubes, ovens, illuminators and solar lampshades. Corrosion resistance: The corrosion resistance of aluminium-zinc steel coil is mainly due to aluminum, aluminum protection function. As the zinc wears away, the aluminum forms a dense layer of aluminum oxide that prevents corrosion resistance from further corroding the interior. 3. Economy: Because the density of 55% Al-Zn is lower than that of Zn, the area of aluminized zinc plate is more than 3% larger than that of galvanized steel plate under the condition of the same weight and the same thickness of gold plating. 4. Easy to paint on The aluminized zinc plate has excellent adhesion to the paint and can be painted without pretreatment and weathering. The coating adhesion of the gold layer of aluminum zinc plate is excellent, so it can be directly coated on advertising board or general use board without pretreatment. 5. Aluminium-zinc plated steel plate has an ornate silver-white surface. 6. Aluminized zinc steel plate and galvanized steel plate have similar processing performance and spraying performance.

Send Email Details -

Hot

750mm Ppgi corrguated Roofing Sheets

Color steel tile, also known as: color pressure tile, is the use of color coating steel plate, by roller cold bending into a variety of wave type of pressure plate. It is suitable for industrial and civil buildings, warehouses, special buildings, large span steel structure house roof, wall and inner and outer wall decoration, with light weight, high strength, rich color, convenient construction, seismic, fire, rain, long life, free of maintenance and other characteristics, has been widely promoted and applied.

Send Email Details -

Hot

Galvanized corrguated Roofing Sheets for warehouse

galvainzed corrguated roofing sheet made from galvainzied sheets directly, Galvanized sheet is a steel plate with a layer of zinc on its surface. Galvanizing is an economical and effective anticorrosion method often used. About half of the world's zinc production is used in this process. Galvanizing is to protect the steel surface from corrosion and extend its service life. Galvanized sheet classification according to the production and processing methods can be divided into the following categories: (1) hot dip galvanized steel plate. A sheet of steel is dipped into a molten zinc bath so that it adheres to a sheet of zinc on its surface. At present, the continuous galvanizing process is mainly used for production, that is, the steel plate into a roll of continuous immersion in the melting of zinc plating tank made of galvanized steel plate; ② Alloyed galvanized steel plate. This steel plate is also made by hot dip, but immediately after the trough, it is heated to about 500℃, so that it generates zinc and iron

Send Email Details