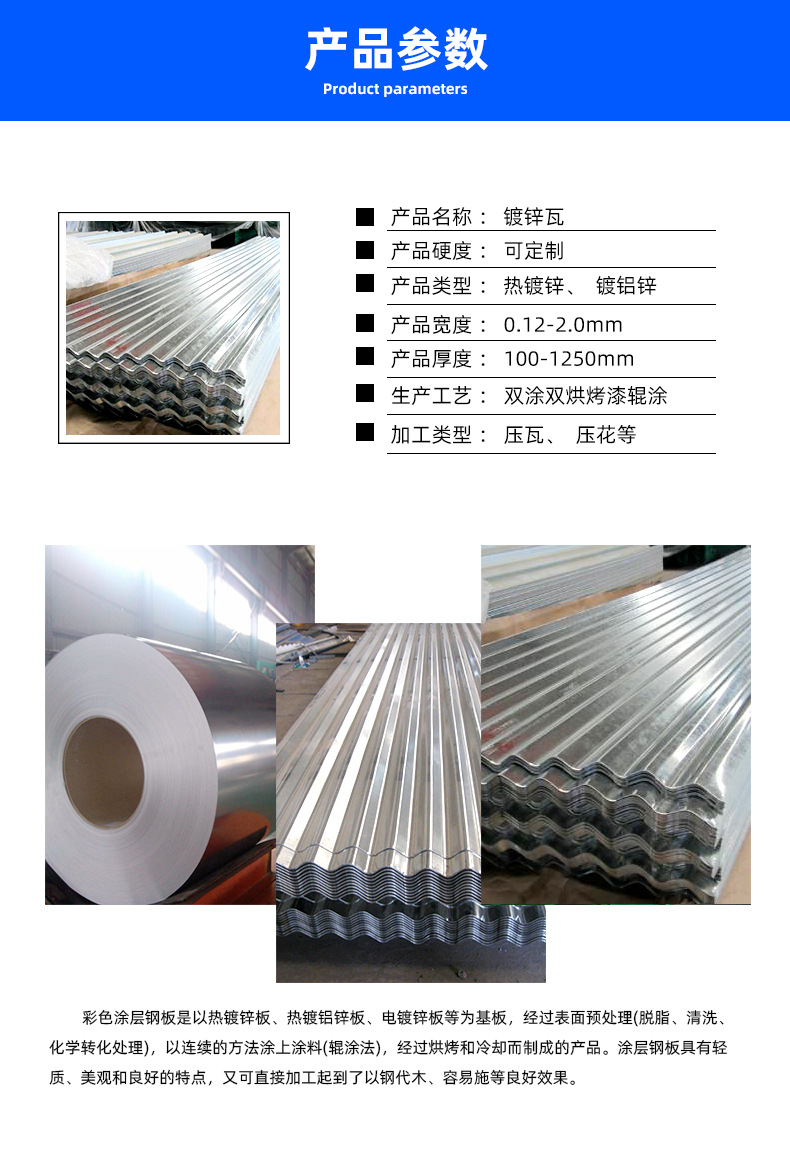

Galvanized corrguated Roofing Sheets for warehouse

Brand : Sincere

Product origin : Tianjin, China

Delivery time : 20days-25days

Supply capacity : 50000tons per month

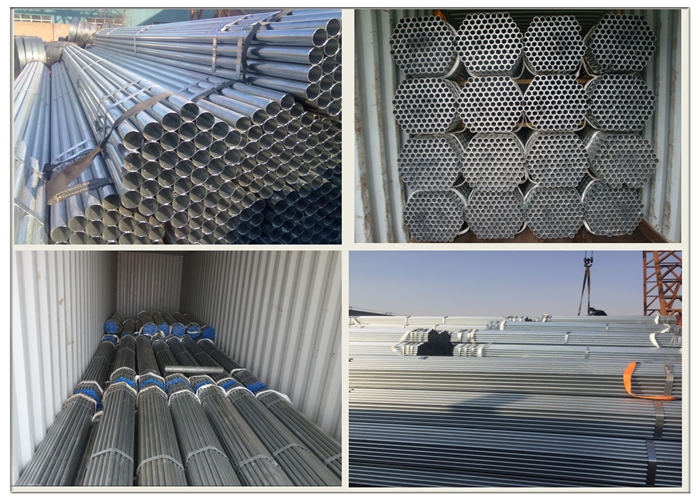

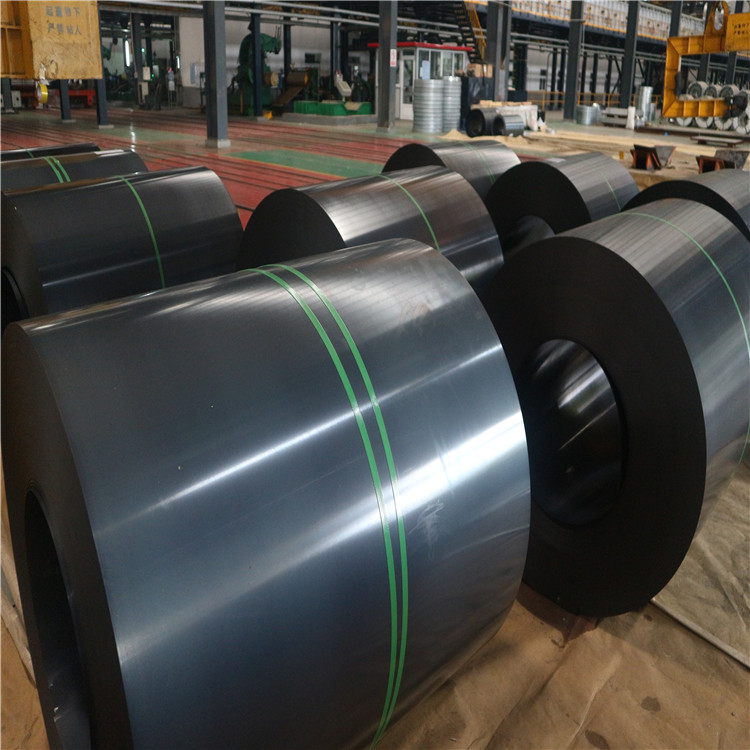

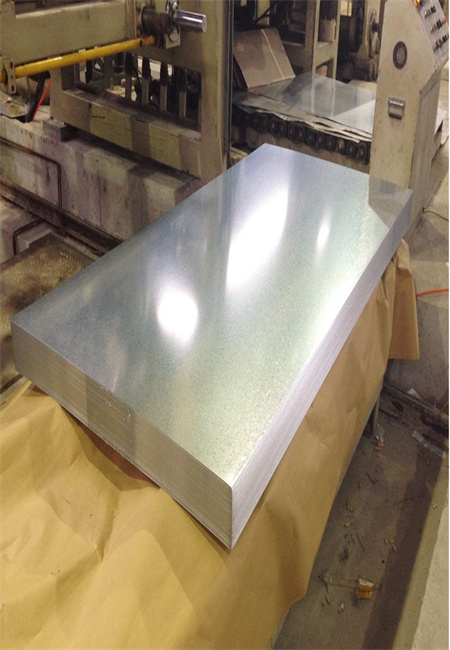

galvainzed corrguated roofing sheet made from galvainzied sheets directly, Galvanized sheet is a steel plate with a layer of zinc on its surface. Galvanizing is an economical and effective anticorrosion method often used. About half of the world's zinc production is used in this process. Galvanizing is to protect the steel surface from corrosion and extend its service life. Galvanized sheet classification according to the production and processing methods can be divided into the following categories: (1) hot dip galvanized steel plate. A sheet of steel is dipped into a molten zinc bath so that it adheres to a sheet of zinc on its surface. At present, the continuous galvanizing process is mainly used for production, that is, the steel plate into a roll of continuous immersion in the melting of zinc plating tank made of galvanized steel plate; ② Alloyed galvanized steel plate. This steel plate is also made by hot dip, but immediately after the trough, it is heated to about 500℃, so that it generates zinc and iron

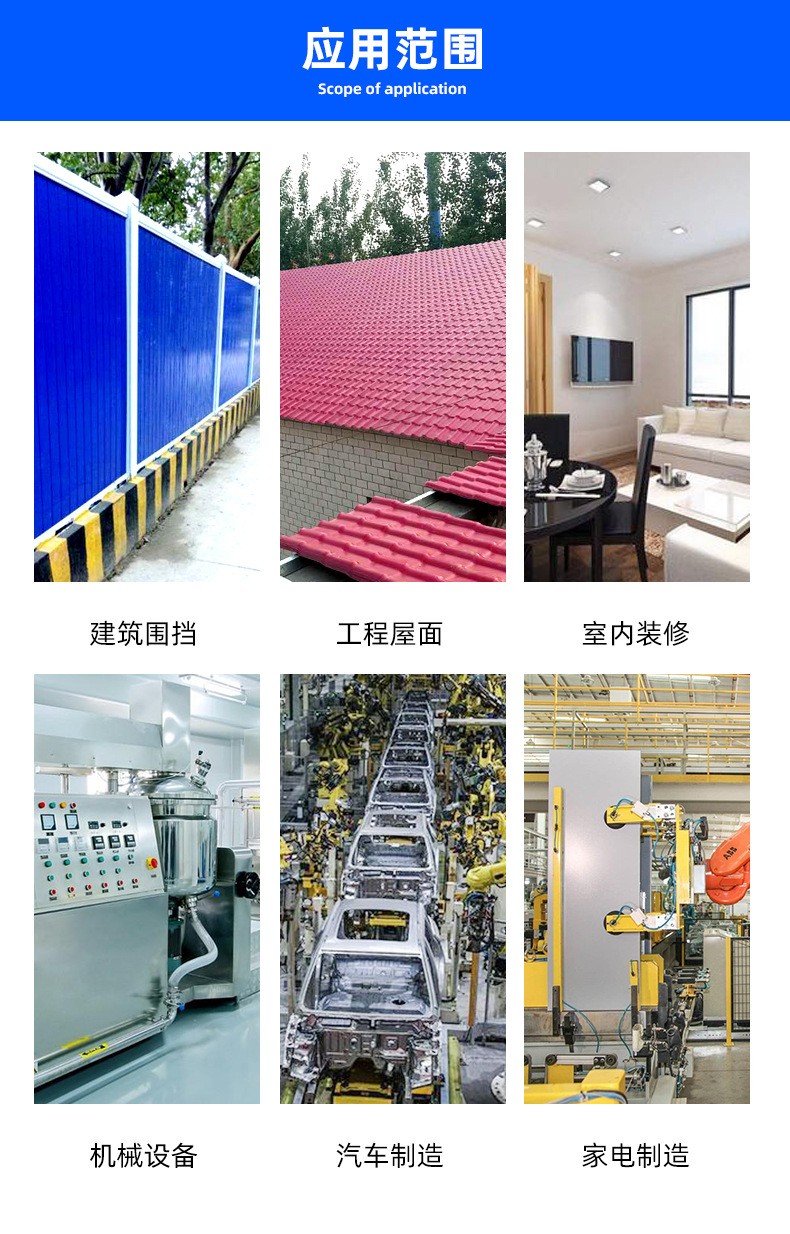

Galvanized corrugated board is made of galvanized sheet pressed by hot dip galvanizing process. Galvanized plate is to prevent the surface of the steel plate from corrosion, prolong its service life, coated with a layer of metal zinc on the surface of the steel plate, this coated steel plate is called galvanized plate or galvanized steel plate. Galvanized sheet is widely used in construction, light industry, automobile, household appliances, electronics, agriculture, animal husbandry and fishery, commodity packaging and other industries.

product name : GI roofing sheets

hardness: depends on client requirement

width range : 100-1250mm

thickness range : 0.11-2.0mm

production process: Double coating double coax baking roller coating

Processing type: pressure tile embossing and so on

we can accept small quantity, if you have other requirement pls contact us directly. if you need sample we can arrange it , sample is for free, but the freight paid by your side, hope you can understand, thanks. waiting for your kind and early inquiry.